Convection mixing, diffusion mixing, shear mixing. The barrel rotates 360°continuously with three-dimensional movement characteristics, so that the materials are mixed from agglomerated to dispersed state and mixed with each other, and there is no dead angle when mixing to realize the full convection and diffusion mixing of materials. Work will be a variety of powder or granular materials through the vacuum conveying, screw conveyor or artificial way of feeding into the double cone container, with the capacity of continuous rotation, the material in the container for complex impact movement, welded scraper blade on the inner wall of the barrel passive drive material left and right convection, interpenetration, material in the cone to produce shear, convection, diffusion and other composite movement, so as to achieve the purpose of uniform mixing.

Product introduction

— Innovative process, efficient mixing—?

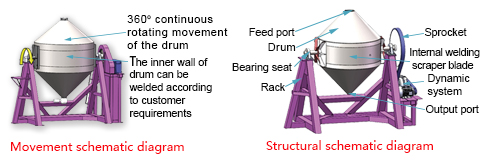

MS large double cone batch mixer is composed of double cone barrel, frame, spiral scraper blade, cylinder rotation power, equipment shell, etc. The 360° continuous rotation of the cylinder makes the materials from the agglomeration to the dispersion state and doping with each other. There is no dead Angle in the mixing, so as to realize the full convection and diffusion mixing of the materials. The welding scraper blade inside the barrel makes the material inside the barrel produce flocculation mixing, spiral scraper blade can be passive shear material, accelerate the mutual convection and diffusion between materials, destroy the material in the form of pure rolling motion, working process without dead Angle, no deposition, can make the mixed material quickly reach uniform consistency.

MS large double-cone batch mixer is suitable for enterprises to mix the products of multiple batches of mixing tasks into a large batch, so as to reduce the labor intensity of workers to ensure the consistency of product performance of large batches. Our company can design the mixing container size according to the user's batch, so as to be strong and durable, stable operation and safe use.

Structural diagram

— ?Multiple power, higher efficiency?—?

Product characteristics

— Make with ingenuity and do a good job of each product?—?

Related products

![]()

Our advantage

— Quality assurance, high efficiency and uniformity—?

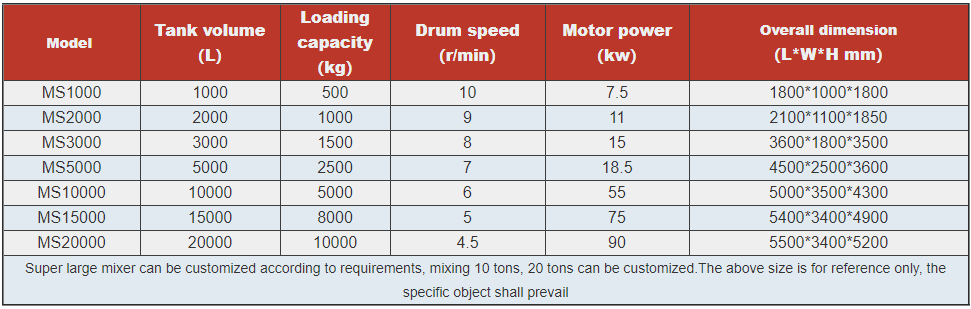

Product parameter

— customized, complete specifications—?

Matching products

— Customized to meet various needs—?